Myths Debunked: Stiffer Forks DON’T Steer Better

To celebrate Bicycle Quarterly‘s 15th anniversary, we are looking at myths in cycling: things we used to believe, but which we’ve since found out not to be true. This week, we have a ‘double feature’ that looks at fork blades. In the first post, we looked at whether they flex enough to improve comfort. Here we examine the belief that stiffer fork blades make the bike steer better.

Looking at Hahn cornering hard on the comparatively flexible Kaisei ‘TOEI Special’ fork blades (above), you can see that the wheels are perfectly aligned as he scythes around this fast downhill corner. His bike steers no differently from a bike with ultra-stiff fork blades. This goes against the widely held belief that a stiff fork offers more ‘precise’ steering.

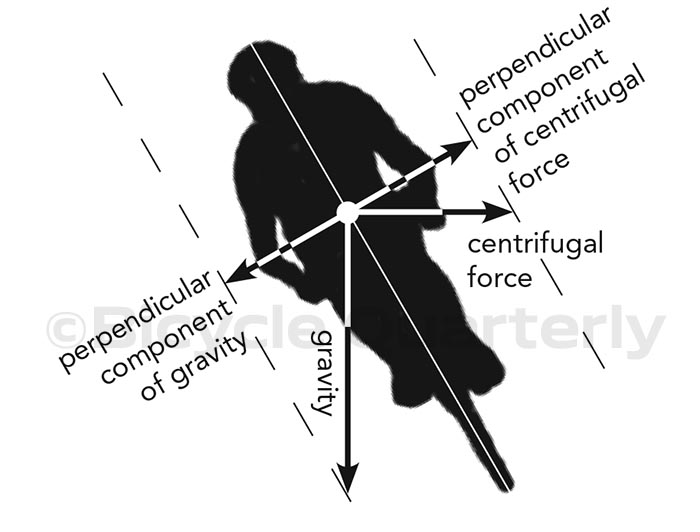

Stiffer setups improve the steering response in cars and tricycles, where the forces of cornering flex the suspension components. On a two-wheeler, those forces are aligned with the centerline of the bike, otherwise, the rider would fall over (above). Even when you corner hard, the centrifugal forces don’t cause the fork to flex.

At low speeds, the front wheel turns at a greater angle, which puts small lateral loads on the fork, but since you aren’t going fast, you won’t notice the little flex this causes. The one exception is tandems: Due to their long wheelbase, you can feel the flex of the front wheel when cornering very hard on tight mountain hairpin turns.

At high speeds, as in the top photo, the fork turns very little even when you corner hard, so the flex is insignificant – even on a tandem.

The only time you put significant side loads on the bike is when you ride out of the saddle. What you realize then is that the lateral flex of the front wheel is far greater than that of the fork.

Climbing out of the saddle on the same bike with two different front wheels confirmed this: On a wheel with a ‘narrow’ SONdelux generator hub (right), the rim rubbed on the brake pad. With the ‘Wide-Body’ model (left), the rim never touched the brake pads, because the wider flanges make the wheel laterally stiffer. The difference in the flex of the wheels was very noticeable. (Same rim, same number, type and tension of spokes in both wheels.)

By comparison, the fork blades flex only very little: Riding the same ‘Wide-Body’ wheel on bikes with different fork blades (standard vs. flexible Kaisei ‘TOEI Special’), we never had the rim rub on the brake pads – even flexible fork blades are plenty stiff for riding out of the saddle. You can easily test that by pulling sideways on your front rim while holding the handlebars steady. You’ll see the wheel flexing, but there won’t be any visible flex in the fork blades.

Even a flexible wheel corners just fine – I haven’t heard anybody talk about the poor handling of aerodynamic wheels with few spokes (and low lateral stiffness). Still, there is no benefit to a laterally flexible wheel… We asked Schmidt to make the ‘Wide-Body’ hubs for us, because they don’t just reduce brake rub – they also make a much stronger wheel. That allows you to use fewer, thinner spokes, which improves the wheel’s shock absorption, weight and aerodynamics.

The one time when you don’t want your fork blades to flex is when you are braking hard. The longer the lever, the greater the force – so fork blades taper as they move away from the hub. The tops of fork blades are ovalized to resist the loads of braking, rather than side-to-side flex. Thanks to these features, even the flexible ‘TOEI Special’ fork blades are more than stiff enough for hard braking. Their flex is concentrated at the bottom of the blade, where the forces of braking are small.

Disc brakes are a different matter, as the forces of braking are fed into the fork blade where the caliper attaches. That changes everything with respect to fork blades. Using flexible forks with disc brakes will require more thought and testing.

Contrasting with the myth, slender fork blades actually improve cornering, because they absorb bumps that would otherwise unsettle the bike. If your bike skips over bumps, the tires lose traction…

If you are a powerful sprinter, the suspension of the fork blades can be a disadvantage: When you work the bike extremely hard while sprinting out of the saddle, slender fork blades can feel a bit like a suspension fork that bobs with your pedal strokes, albeit to a much smaller degree. Even track sprinters don’t need ultra-stiff fork blades; they might choose something like the Kaisei ‘Standard’ fork blades. In fact, since they also rock the bike much more from side-to-side and don’t have brakes, they often use round fork blades.

For the rest of us, we’ve found that the Kaisei ‘TOEI Special’ fork blades (above) take the edge off large bumps to improve comfort, tracking in corners and speed. Steel is a great material for fork blades, because it can flex without affecting its durability: our ‘TOEI Special’ fork blades have been 100% reliable over tens of thousands of miles. I consider them a key component of our bikes, making them faster and more enjoyable at the same time.

Update 11/2020: We’ve just published our new book ‘The All-Road Bike Revolution’ with all the research that has changed cycling in recent years. Find out why wide tires can be fast, how to find a frame that optimizes your power output, and how to get a bike that handles like an extension of your body. More information is here.