One of the 5 Fastest Tires in the World

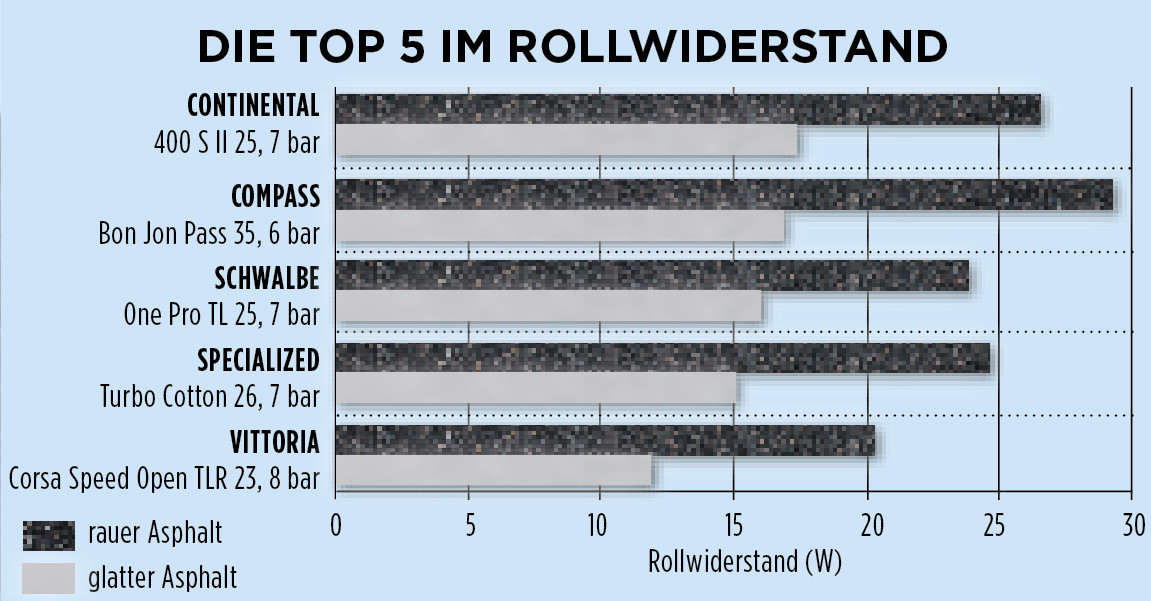

Recently, the German magazine TOUR published a table showing the ‘five fastest tires in the world.’ We are excited to see our Rene Herse Bon Jon Pass 700C x 35 mm tires (back then still under the Compass label) on this list, in the company of the fastest racing tires. A 35 mm-wide tire on a list that otherwise includes only tires between 23 and 26 mm wide! That by itself is already cause for celebration. It means that our casings really are among the very fastest in the world.

And since all our tires use the same casings and construction, TOUR’s results apply not just to the Bon Jon Pass, but to all Rene Herse tires. I was surprised that they tested the Standard casing. I would love for them to test the Extralight, which we know from our own experience to be even faster.

What is interesting is that the Rene Herse tire scored superbly on smooth asphalt (light gray bars), but a little less well on rough asphalt (dark bars). This doesn’t match our experience, where wider tires provide advantages especially on rough roads. The reason is simple: TOUR tested without a rider on the bike. This measures the hysteretic losses in the tire, but it neglects the (much more important) suspension losses that occur as the rider’s body and bike vibrate. (Click here to learn more about suspension losses.)

This means that TOUR’s testing overlooks one of the main advantages of wide tires: their superior comfort, which also makes them faster. In other words, with a rider on the bike, especially on rough asphalt, the Rene Herse tire would be even faster than it appears in TOUR’s testing.

It doesn’t really matter: We are proud that the Rene Herse Bon Jon Pass scored so well, especially since it is intended as an all-round tire, not an all-out racing tire. The Bon Jon Pass is suitable for gravel racing and has 3 mm-thick tread for many miles on the road. Compare that to the Vittoria with its 0.8 mm-thick tread, which is intended only for time trials, and even then, it’ll wear out quickly.

The excellent performance of the Rene Herse tire shows once again why wide tires have revolutionized cycling: You wouldn’t want to ride the other tires on TOUR’s list on anything but the smoothest, cleanest roads. And yet with wider tires, we can ride some of the world’s fastest tires on the backroads where cycling is at its most beautiful.

Further reading:

- TOUR’s test report with the chart of the five fastest tires (German language)