Introducing Rene Herse Cantilever Brakes

The new René Herse cantilever brakes are here! Prototypes of these brakes were one of the secrets that made Peter Weigle’s bike at this year’s Concours de Machines so light. They weigh just 75 g per wheel including bolts, springs and pad holders (without pads).

How can the René Herse cantilever brakes be that light? After all, even carbon cantilevers like the TRP RevoX are 50% heavier at 113 g. The TRP shows what happens when you take a standard brake and try to make it lighter – there is only so much you can do.

The secret of our new cantilevers is simple: They are different in many ways from most current brakes. The credit goes to René Herse, who designed these brakes for the 1940s Concours de Machines technical trials, where his bikes were among the lightest ever made. And yet his brakes weren’t just for weight weenies – they even equipped his tandems. I’ve ridden Herse tandems in the mountains, and the stopping power of the brakes was definitely sufficient.

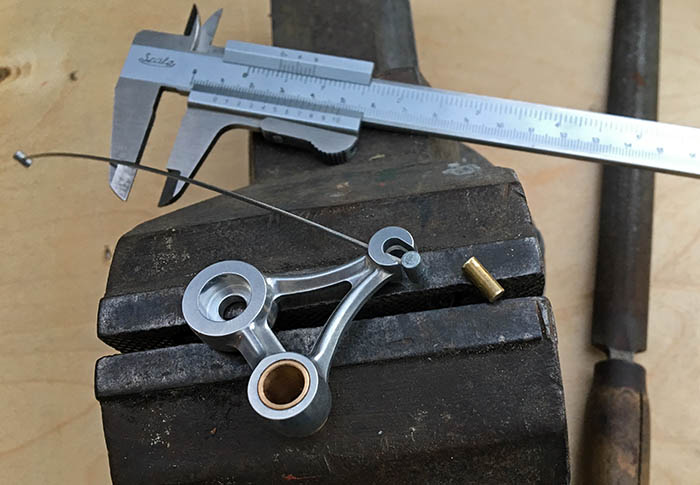

How do you make a superlight brake? You start with an absolutely minimalist arm. Ours is forged from aluminum for ultimate strength.

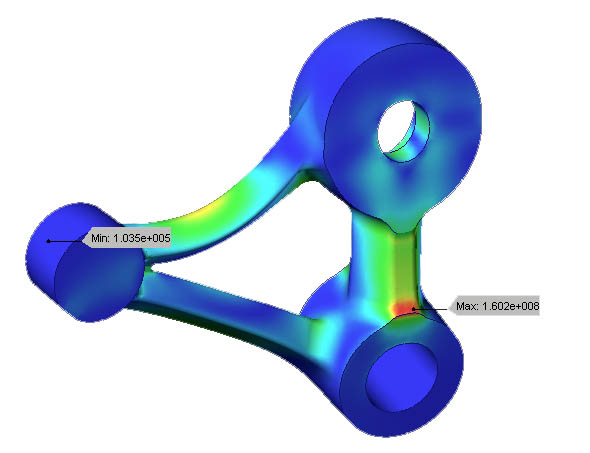

Just as important is the shape – we used Finite Element Analysis (FEA) to model the stress distribution in the arms (above). Blue and green means low stresses. As you can see, Herse’s original design showed no stress concentrations. (The small spot of red is caused by a lack of reference points near the edge, not because the arm is likely to break there.) The FEA model confirms the genius of the ‘magician of Levallois,’ who didn’t need computers to make parts that were light and strong.

The arms are so minimalist that there is nowhere to attach the springs. Drilling holes would weaken the arms, so the springs wrap around them instead. You’ll also notice that there are no screws to dial in the spring tension. They aren’t necessary, because our springs are carefully equalized. You only need to adjust the tension if one spring is stronger than the other – which unfortunately is the case on many cantilevers. Making springs to such close tolerances is more expensive, but it also makes setup easier.

René Herse used post-style pads. (In fact, he may have invented them – earlier cantilever brakes used the same pads as sidepulls, which attach directly with screws.) The advantages of post-style pads are many. First, it makes it easy to adjust for pad wear – you just slide the pads inward. This means that the brakes fit on bikes with a wide range of canti post spacing. The posts also allow adjusting for minor variations in canti post height (as you slide the pads inward, the arm rotates outward, which lowers the contact of the pad on the rim.)

Post-style pads make it possible to make the arms lighter, because they don’t need flat spots with slots where the pads attach. Herse used large eyebolts to attach the pads to the arms. This is one place where our new brakes are even lighter than the originals: Optional titanium eyebolts for the pad holders save weight without sacrificing strength – these bolts are large to fit over the pad holder posts, not because they have to withstand big stresses.

To adjust the toe-in of the brake pads, René Herse simply bent the arms. That worked for him, because his brakes were used only on custom bikes, which were set up in his shop by experienced mechanics. The advantage of this method is that you only bend the arms once, and the toe-in is set forever. Later, you can replace the brake pads without having to set the toe-in again.

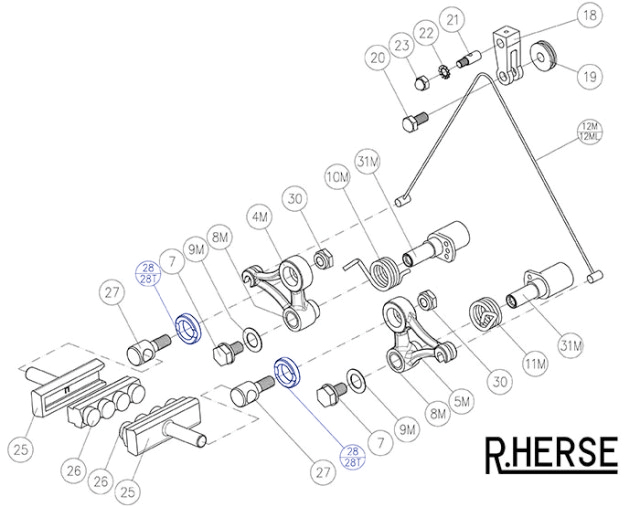

For our new brakes, we offer the option of angled washers that let you set the toe-in (part 28/28T, shown above in blue). This is super-simple and permanent, too, so pad replacement is easy. Since the washers take up extra space, we replace the large aluminum nut on the eyebolt with a shorter steel one. The weight goes up a fraction (4 g), but it’s a great solution for customers who aren’t comfortable bending their brake arms, or for brakes that may be used on many different bikes. (Bending the arms too often can weaken them.)

Like our centerpull brakes, the new René Herse cantilevers use an extra-thin straddle cable. This is made possible with swiveling attachments to the arms, which eliminate stresses to the cable that occur with standard clamp bolts. The thinner straddle cable isn’t just lighter, it also bends more easily around the straddle cable holder. This eliminates the flex you get with thicker straddle cables, which have to straighten first when you apply the brakes, before they can transmit brake power. The thinner straddle cable makes the René Herse brakes more powerful, yet the minimal ‘lost motion’ allows you to set the pads with plenty of clearance to the rim – without the risk of bottoming out the levers. This also means that the René Herse cantilever brakes work equally well with modern ‘aero’ and with classic ‘non-aero’ brake levers.

We’ve tested the new René Herse cantilevers on a variety of bikes over hundreds of miles. They fit over 42 mm-wide tires with 62 mm-wide fenders, or 54 mm-wide tires without fenders. They are designed to work with cantilever posts that are spaced between 62 and 84 mm wide. To work with the ultralight design of these brakes, the height of your frame’s cantilever posts must be within standard tolerances. (Your current brake’s pads should be roughly in the middle of the slots.) If the pads of your current brakes are at the top or bottom of the slots, the René Herse brakes may not fit on your frame.

We are excited that we now can use these amazing brakes on many of our own bikes. And if you’re curious about René Herse himself, we recommend our book on the ‘magician of Levallois.’