Cyclodonia on the J. P. Weigle from the Concours de Machines

Jan’s comment: It’s always interesting to read others’ impressions of our work. Cyclodonia discussed several bikes from the Concours de Machines in detail. Translated and reposted with permission. The French original is available here. The views expressed are those of the original author, not mine. Enjoy!

J. P. Weigle (Lyme – USA)

- 2nd place, Concours de Machines

- Prix de la Légèreté [Prize for the lightest bike]

Looking at this bike, the unsuspecting public (and ‘unsuspecting’ includes a good part of the riders in the Cyclosportive Les Copains held the same weekend as the Concours de Machines) might think this is an old bike, built 60 or 70 years ago and restored carefully. And yet, the bike presented by J. P. Weigle did not use any old parts that had been pulled from the drawers of a collector.

But why redo what already had been done 70 years ago, especially in a competition where originality was the best way to distinguish your bike? The conviction of Jan Heine, rider and future owner of this bike, a conviction which he has defended for several decades in his magazine Bicycle Quarterly, and which is supported by tests that are of a rigor which we would love to see in the French cycling press, is as follows: During the 1940s and 1950s, the French randonneur bike, thanks in part due to the influence of the Concours de Machines, had achieved a perfect balance of performance, light weight, reliability, comfort and elegance.

Evidently, this is a counterintuitive opinion when the cycling industry has introduced multitudes of new standards and innovations. In any case, it was difficult to show the potential of the products and standards of the randonneur bike of the “grande époque,” when they had mostly disappeared. Hence Jan Heine has re-issued a selection of components that no longer were available, under the Rene Herse brand, notably tires, brakes and cranks. The J. P. Weigle presented an opportunity to showcase Rene Herse products in the Concours de Machines.

The absence of any technical mishaps on the difficult roads of the bike test, the speed of its pilot, and the award for the lightest bike, which the Weigle obtained in addition to the silver medal overall, all show that this was undoubtedly one of the best-performing bikes in the event.

A lightweight bike

The light weight of the bike is first and foremost the result of J. P. Weigle skill. He chose a selection of lightweight tubes, and then he chased every gram while building the frame. The tubes are a “Special Mix” according to the sticker. One can assume that the builder used Kaisei fork blades, but that is all we’ll know: J. P. Weigle keeps his secrets to himself.

But it is also a careful selection of the components that brought this fully equipped randonneur bike very close to 9 kg (9.1 kg with pump and bottle cages, but without bag).

The Herse cranks showed the intent: Drilled chainrings brought only marginal weight savings, and they also spoiled the beautiful lines a little, but they drew attention to the fact that this was a bike for the Concours de Machines. (Last year, it was Andouart who gave in to the same temptation.)

This crank is far from a relic. It is interesting for two reasons: It is one of the lightest on the market, and it offers an unrivaled choice of chainrings with the same bolt-circle diameter: single, double or triple. In each configuration, it can be equipped with chainrings from 24 to 52 teeth. Here it was assembled with 46 and 30 teeth, particularly well-suited to hilly terrain, and yet practically impossible to obtain on a classic double crank with a five-arm spider.

The use of titanium was another means of saving a few grams. There were, for example, the bolts for the brake pads, difficult to see:

Other components were drilled and machined to remove material. One of the most noticeable pieces of work were the quick release levers:

The choice of brakes and cables provided another significant weigh reduction. One notes that the three lightest bikes at the Concours (Weigle, Grand Bois and Tegner) all featured downtube shift levers and centerpull brakes – while the vast majority had chosen the obvious solution of disc brakes and shift levers on the handlebars.

Downtube shift levers (together with non-aero brake levers) are among the distinctive features of vintage bikes. For many cyclists, it’s unimaginable to return to such a shifter. And yet the great speed of the rider during the two bike tests of the Concours shows that this type of shifting system remains perfectly fine for cyclotouring, even at a very intense pace.

Who knows, after the return of vinyl records and Polaroid photos, perhaps downtube shifters will be the next great revival of the early 21st century? Note that Weigle’s solution is far from outdated:

Exposed cables are lighter, have less friction and are easier to remove (thanks to slotted cable stops) for maintenance or when disassembling the bike. We will see later that this choice of brakes and shifters also was chosen to facilitate packing of the bike for travel. And in the rare cases where cable housing was used, it was extralight and made from aluminum.

But even if the bike won the prize for the lightest bike, several of J. P. Weigle’s choices show that weight reduction was not the only concern. Without a doubt, aesthetics also played a role, starting with the frame’s lugs that must have added a few dozen grams compared to a fillet-brazed frame. The Rene Herse straddle cable holders also are more refined aesthetically than simple Mafacs, but also heavier. To make up for it, the screws that hold the brakes are drilled:

The stem isn’t made from aluminum, but custom-fabricated from steel. One can bet that J. P. Weigle has used all his skill to limit its weight to an absolute minimum:

And as if to show that light doesn’t mean spare, J. P. Weigle even allowed himself the luxury of integrating a system to lock the decaleur, a good idea in view of Ambert’s rough roads:

And the comfort of a leather saddle clearly had priority over the light weight of a carbon saddle.

Proof that extra light does not mean poorly equipped, the mudflap – an accessory that is very dear to J. Heine – had not been forgotten:

The all-day ride in the rain and through mud was a perfect occasion to test, under real-life conditions, the efficiency of this accessory intended to protect the rider’s feet and the front of the drivetrain. The result is a bit mixed:

To the defense of the Weigle team, the other bikes of the Concours were not in better condition as they crossed the finish line, and the Weigle remained quite clean after such a hard ride. [JH: I had to remove the mudflap on the rough trails during the first day, because it got caught on the long grass and huge rocks we had to traverse.]

I had doubts about the positioning of the pump on seatstay, close to the rear wheel and thus in the path of spray. But the verdict was rather clearer, even on this rainy day. The pump remained as shiny as it had been before the morning start.

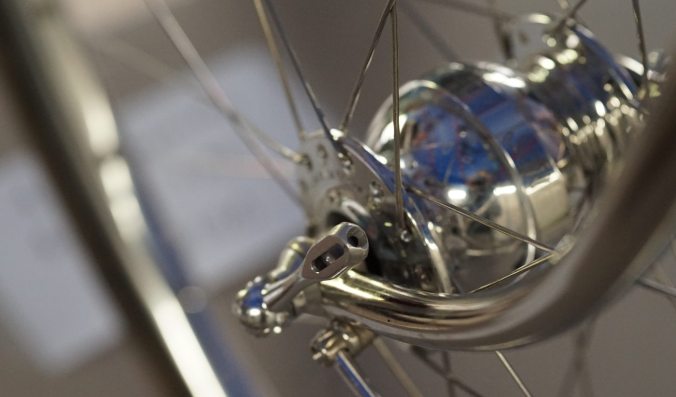

The choice of the generator hub was another example where the search for the lightest weight was not the last word. The SON Delux hub is a descendant of a model intended for small wheels where the dropout spacing often is 75 mm. Used on a large wheel, the resistance is lower, but it also produces less current. The latter point has stopped being a real issue with the amelioration of LED headlights, and the Delux has become interesting for cyclotourists looking for performance. Its only fault stems from its origins: the flange spacing is narrower than ideal for a 100 mm axle. The Wide-Body version corrects this problem and offers a flange spacing optimized for standard forks.

In fact, the greater the flange spacing, the stronger is the wheel when subjected to lateral loads. J. P. Weigle chose this version even though it weighs almost 30 grams more than the standard version. To make up for this, the dropouts have been custom-made and are smaller than the standard SON SL dropouts. They incorporate the insulated plate that allows connecting the hub electrically without any apparent wires. In addition to its elegance, the SL system simplifies the removal of the front wheel.

Lighting

Lighting is one of the few places where Jan Heine agrees that current components are superior: Over the last 20 years, generator hubs, LED headlights and optics specifically designed to project an even beam onto the road have greatly improved night-time cycling.

The electrical circuit on this bike is especially well thought-out: SON SL connector-less hub, switch integrated into the stem cap, and a taillight that is brazed onto the seat tube and connected by internal wires:

Rinko

Several builders at the Concours showed ideas for folding or disassembling the frame, so the more discreet Rinko bike risks being overlooked: The idea of Rinko consists of choosing the components in such a way that a quick and simple disassembly is possible without any modification of the frame itself, thus avoiding extra weight or, worse, a change in the ride characteristics of the frame. In fact, when pressed for time, the possibility to disassemble the bike in less than 15 minutes makes the Rinko method competitive with frame couplers, which are more costly and not always results in a package that is stable enough to stand on its own.

[JH: Cyclodonia did not have a photo of the bike in its Rinko’ed state, so I added this image of the free-standing package to illustrate how it works.]

When packing a bike Rinko-style, the wheels are placed on either side of the frame. The most compact method consists of removing the fork, while the front wheel remains installed. This requires removing the handlebars, which will be placed on one of the wheels. On the Weigle, the handlebars can be removed from the bike in a few instants: the slotted housing stops and the cantilever brakes allow removing the brake cables in just seconds:

A chain hook is placed very high on the seat stay, and the rear fender can be split to facilitate the operation. The little wing nut allows to remove the upper part of the rear fender without tools:

The chainstays and fork blades are nickel-plated: This lends the bike a timeless beauty, but most of all, it protects against the scratches: The rear dropouts form two of the three contact points with the ground of the Rinko package. [JH: The back of the saddle forms the third.]

Classic

What makes the Weigle so classic is that its aesthetic decisions always appear to be justified by practical function.

Finally, chance sometimes does a good job, too. The integration of the bell into the stem had been forgotten, so J. Heine placed it under the saddle. A position that is hard to reach in emergencies, but a beautiful reference to the bikes of the classic age:

The Rene Herse components have been featured in an earlier article of the blog.

More information about the J. P. Weigle bike:

- J. P. Weigle’s Flickr page

- Article about the Concours bike on Jan Heine’s blog