Making Strong and Durable Wheels

When building a bike, one important decision concerns the wheels. How do you get the best performance and still make your wheels strong enough to withstand 20,000+ miles of riding on rough roads without needing service?

By now, most cyclists know that spokes don’t break from overloading, but from fatigue as the spoke is loaded and unloaded when the wheel rotates. The wheel flattens at the bottom, which unloads the spoke at 6 o’clock. With each wheel revolution, every spoke passes through that spot, where it is slightly detensioned, and then tensioned again. Over time, that causes the spoke to fatigue.

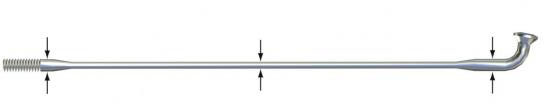

To get the maximum life out of your spokes, you want the detensioning to be as small as possible. That is what double-butted spokes (above) are for: They are thinner in the middle, so they can stretch more, which means that they don’t detension as much as a thicker spoke would. Yet the ends, where spokes fail if they break, are thick and thus will last a long time. It may seem counterintuitive at first, but the thinner mid-sections make double-butted spokes more durable than thicker straight-gauge spokes.

Wheels tend to go out of true when you hit a bump and a spoke detensions so much that it goes slack. As the spoke is tensioned again, the nipple unwinds a bit. Now the spoke has less tension, so it will go slack more often, allowing the nipple to unwind more and more… For more information about the basics of wheel building, I recommend the late Jobst Brandt’s excellent book The Bicycle Wheel.

Now, let’s look at the specifics of building a strong wheel.

How many spokes do you need? For many years, 36 spokes was the standard (above), then it became 32 as modern spokes became stronger. On my René Herse (top photo), I use a 28-spoke front wheel. I built the wheel six years ago and never touched it again. If the rim hadn’t cracked (different story!), I am sure it would still be going strong today.

We can use fewer spokes, because the wider tires we ride today transmit far fewer shocks to the rim. Imagine hitting the bump above with a 23 mm tire: Even if you don’t bottom out, your tire is so hard that much of the impact will be transmitted to the rim. The big, soft tire not only transmits less shock to the rider, but also to the rim.

With smaller 650B or 26″ rims, the spoke bracing angle is greater, which makes the wheel stronger as well. That means that 28 spokes are plenty, even for rough roads.

However, the SON Delux hub I usually ride on my Herse has very narrow flanges, which results in a smaller spoke bracing angle, negating the benefits of the smaller 650B rims. For the Oregon Outback 363-mile gravel race, I put on a wheel with an old SON20 generator hub that has wider flanges (above). When you negotiate rough terrain, your wheel can slip while it’s pointing sideways, then suddenly catch and regain traction. If the wheel is not strong enough, it can collapse into a potato-chip shape, and your ride is over.

We wanted a wider spoke bracing angle, so we asked Schmidt Maschinenbau for the Wide-Body Delux hubs, which have the widest flange spacing possible and thus build into the strongest wheels. Compass now offers these hubs in 28 holes, in addition to the 32h and 36h that have been available for a few years. If I had a Wide-Body hub on my bike, I would have been perfectly happy with 28 spokes for the Oregon Outback.

There are cases when a front wheel with more than 28 spokes makes sense. With disc brakes, your flanges are more narrowly spaced to make room for the rotor – that is why there is no Wide-Body Disc hub – and the entire force of braking is transmitted by the spokes. In this situation, a 28-spoke wheel usually is OK, but 32 spokes gives you an additional margin of safety. The same applies for 700C wheels (larger-diameter rims result a smaller spoke bracing angle), or for very heavy bike/rider combinations. For tandems, I’d go with 36 spokes.

There are cases when a front wheel with more than 28 spokes makes sense. With disc brakes, your flanges are more narrowly spaced to make room for the rotor – that is why there is no Wide-Body Disc hub – and the entire force of braking is transmitted by the spokes. In this situation, a 28-spoke wheel usually is OK, but 32 spokes gives you an additional margin of safety. The same applies for 700C wheels (larger-diameter rims result a smaller spoke bracing angle), or for very heavy bike/rider combinations. For tandems, I’d go with 36 spokes.

Compass offers the excellent SON Delux Wide-Body hubs with 28, 32 and 36 holes, so you can choose the spoke count that is right for you. We also offer the Delux for disc brakes with 32 holes, both in quick release and thru axle versions (above).

What about the rear wheel? Here, too, the answer is: “It depends.” If you have a strong rim, then 28 spokes may be enough. When HED send us test wheels with their Belgium rims a few years ago, they used 28 spokes front and rear, and they held up fine even when we rode them on mountain bike trails. One reason is that the rear wheel never sees significant side loads.

However, the rear wheel has a much narrower spoke bracing angle to make room for the freewheel/cassette. That is why British builders often used rear wheels with 4 or 8 more spokes than the front. I did the same on my René Herse, which has 36 spokes on the rear. Most wind tunnel studies indicate that the rear wheel is in such turbulent air that its aerodynamics don’t matter much, and the little extra weight isn’t a big deal, either.

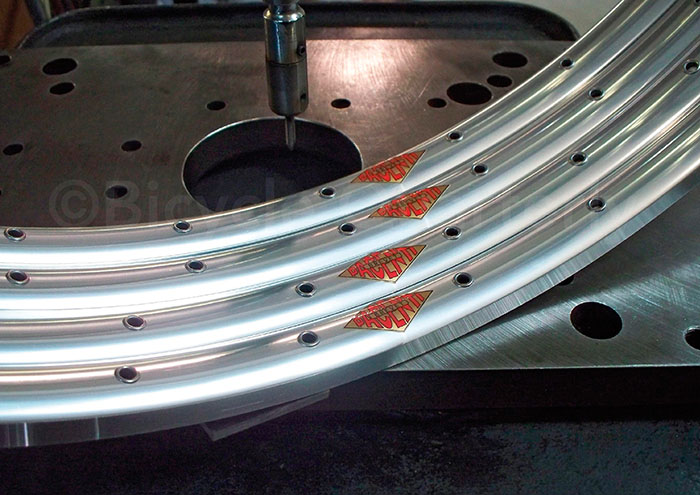

Next, let’s talk about rims: Most rims today are stiff and strong. If rims crack, it’s usually caused by poor design or sub-standard materials. Once you’ve eliminated those problems, what you want from your rims is a good fit of the tires. With classic rims, it needs to be good enough to seat the tire automatically as you inflate it. And the tire shouldn’t come off even if you have a sudden blowout on the front. With tubeless-ready rims, the fit needs to be even more precise, so the tire seals easily and doesn’t blow off the rim despite lacking a tube that reinforces the joint between tire and rim.

Compass offers two rims:

- The brand-new Pacenti Brevet rim combines classic appearance with tubeless-ready construction. Compass has them in stock in 28 and 32 holes.

- The HED Belgium Plus is a modern, lightweight, wide semi-aero rim. It is tubeless-compatible, with a tire fit that is consistently excellent. A few of us have been riding them for a few years now (above Theo’s bike), with zero need for truing and easy tire mounting. Black anodized and available in 28 and 32 holes for rim brakes, and in 32 holes for disc brakes.

For each of these rim/hub combinations, we now offer spoke packages with the highest-quality, double-butted, superlight Sapim Laser spokes (2.0 – 1.5 – 2.0 mm) and aluminum nipples. That makes it easy to build a generator hub wheel that is perfect for your intended use: Just select your hub and your rim, and then order the spoke package that goes with this combination. (We also offer the spokes individually.)

Click here for more information about Compass wheel goods.