The Price of Performance

Why do high-end bikes and components cost so much more than budget offerings? Both racing bikes in the photo above are made from carbon fiber. Both are equipped with multi-speed drivetrains and Shimano STI shifters. Both have narrow 700C tires. One may be a little lighter, but does that justify charging so much more? Both are fine bikes, so what do you get when you pay so much more in a bike?

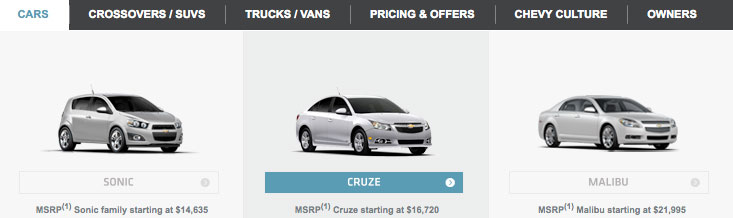

If you look at it from the perspective of buying cars (or washing machines, or furniture), the pricing of bikes does indeed seem odd. When you buy a more expensive car from the same maker, you usually get a larger car, with a bigger engine. More money buys more car.

Many car buyers would be surprised to learn that a larger car (or refrigerator) does not cost more to make. The steel, aluminum and plastic that goes into a car makes up only a small fraction of the price you pay. It’s insignificant, really. Yet car makers charge significantly more for bigger cars, because they can. And they push their larger models, because their profits are so much higher.

In the bike world, it rarely makes sense to promise you “more” in return for a higher price. Imagine the salesperson telling you: “For just $250 extra, I can put you on a 62 cm frame instead of the 60 you are looking at now.” Instead, more money usually buys you a product with better performance.

How do you get more performance?

In a car, you can increase performance simply by increasing the engine size. A 3-litre engine has more power than a 2-litre engine, all things being equal. On a bicycle, the engine size cannot be changed: You are the engine!

Bicycles are like race cars. In race cars, the rules restrict engine capacity and power output. The only way to obtain extra performance in a race car comes through optimizing every component. Of course, that costs much more than boring larger holes into the engine block to increase the cylinder size and thus get more horsepower.

Small race cars are no less expensive than large ones. A competitive race car easily can cost ten times the price of a similar production model. The two Subarus below ostensibly were the same car, both with a 2.0 liter turbo engine. Yet they shared few components, and the race-prepared car cost ten times as much as the production model.

With bicycles, it’s similar, albeit usually not as extreme. You can buy a mass-produced steel touring bike with triple cranks, cantilever brakes and racks for $1500. Why does a custom-made steel randonneur bike cost four times as much?

Like the racing car, the custom-made randonneur bike has every component optimized for performance. A good builder also tends to have more know-how than the “production managers” who spec production bikes, and the bike’s design can be adapted to your needs and desires. So the custom bike already is a better machine for you before it even leaves the drawing board. When it comes to making the bike, the builder starts with better raw materials. He or she uses more expensive processes and much more hand-work to arrive at a final product that performs much better.

How much better? Everybody will notice things like the shock absorption of the fork and the better ride of more supple tires. Other details become more important the harder you ride. When you approach the cornering limit, you really appreciate a bike that has predictable, precise handling. When you ride fast over indifferent roads, you don’t want things to rattle and shake loose. When you ride at night, you notice if your light is mounted so it illuminates the road without blinding you. The harder you pedal, the more you appreciate a frame that gets in sync with your pedal strokes. And the more you ride, the more you will appreciate the increased longevity and safety that comes with higher-quality bikes.

There is no denying that some bicycle companies charge more just because the market will bear it. The Campagnolo Super Record cranks (above left) are by all reasonable measures identical to the Record ones (above right), yet cost significantly more. However, my experience shows that budget parts and bikes rarely work as well as high-end ones. The difference often is in small details, like the effort required to shift gears, or the quality of the bearings. The reduced weight of the high-end components is less important the extra enjoyment they provide while you ride.

My conclusion: You can have fun on any bike, and skill and fitness will make more of a difference than an expensive bike. Often, good enough is just that: good enough. (For example, I’d be perfectly happy with the production Subaru that cost £18,000.) That said, more expensive, better bikes often are more fun to ride, and if you ride a lot, they can be worth the extra money. However, that $ 11,000 Trek seems overpriced for a production bike.