History of Aluminum Cranks

During the development of our new René Herse cranks over the last two years, I have been thinking a lot about crank design. Modern cranks are an interesting story of standards that evolved until nobody remembers why they were adopted in the first place. Here are a few questions that I tried to answer:

- Why do triple cranks have two different bolt-circle diameters?

- Why do makers offer “compact” and regular cranks, when you could make 53-tooth chainrings for “compact” cranks and offer only a single, more versatile model?

- Why do “road” cranks have five-arm spiders, but many “mountain bike” cranks have only four, and some only three?When something doesn’t appear to make sense, it often helps to look at how it evolved over time.

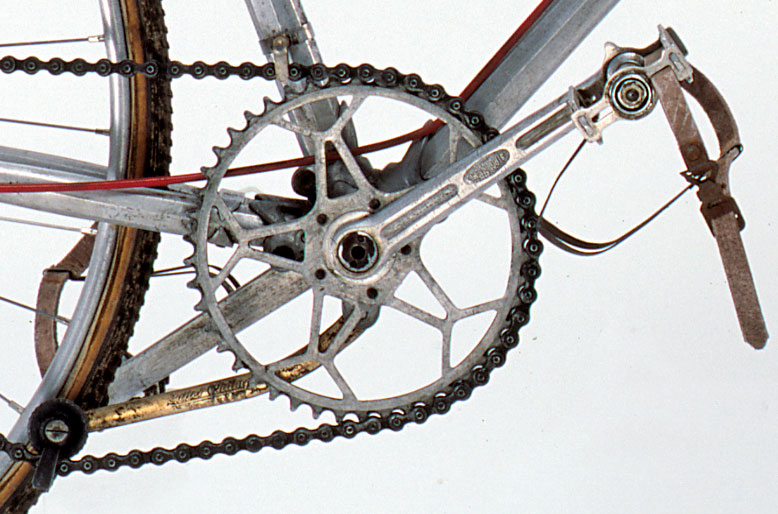

The first successful aluminum cranks were introduced in 1933 by Stronglight (photo at the top). They used a square taper fitting on the spindle instead of the cotters used by most steel cranks at the time. As their name implied, these cranks were strong and light.

They had one drawback. The chainring attached to a small flange on the right crankarm, as was common among cranks at the time. If you ran two or more chainrings, the additional chainrings attached to the big ring with bolts, nuts and spacers. Installing the chainrings on these cranks is a fiddly business. The small bolts are under-dimensioned. It is hard to tighten them enough without breaking them.

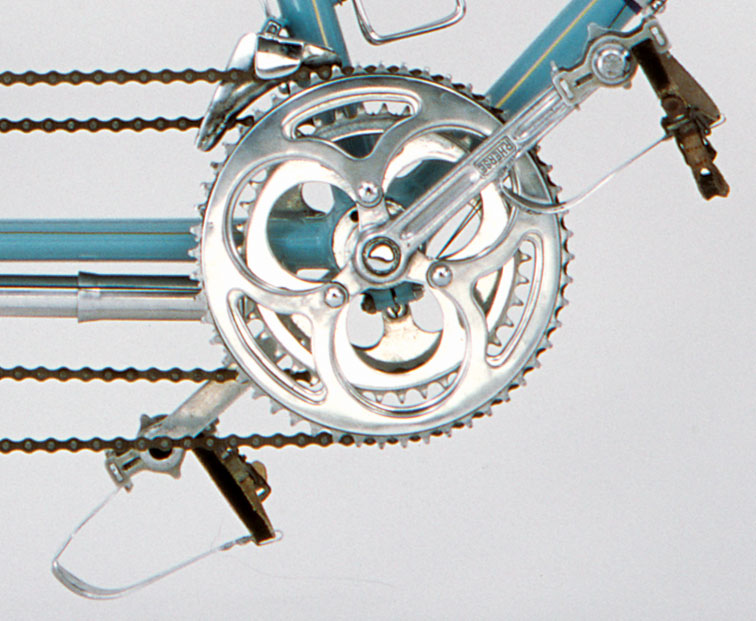

The next modern aluminum crank was offered by René Herse in 1938 (above; 1950s tandem version shown). Herse mounted his chainrings to a larger spider instead of a flange. Using three arms and a bolt-circle diameter of 70 mm, these cranks preserved all the advantages of the Stronglight, while making it much easier to attach the chainrings. The cranks could be set up as a single, double or triple with any chainring combination down to 24 teeth.

When Herse began to offer complete bicycles in 1940, his cranks were available only on his bikes. If you wanted a René Herse crank, you had to buy a René Herse bike. This precluded a more widespread adoption of this great design.

Starting in the late 1940s, Tullio Campagnolo adopted a number of cyclotouring components for racing. The first was the Gran Sport derailleur, which was based on the Nivex parallelogram derailleur. (Campagnolo famously bought two Nivex derailleurs from Alex Singer the year before he introduced the Gran Sport. You can read Bicycle Quarterly’s article on the development of the Gran Sport here.) The Gran Sport was so successful that it set the mold for all modern derailleurs. Even Shimano’s electronic Di2 rear derailleur can trace its ancestry directly to the Gran Sport.

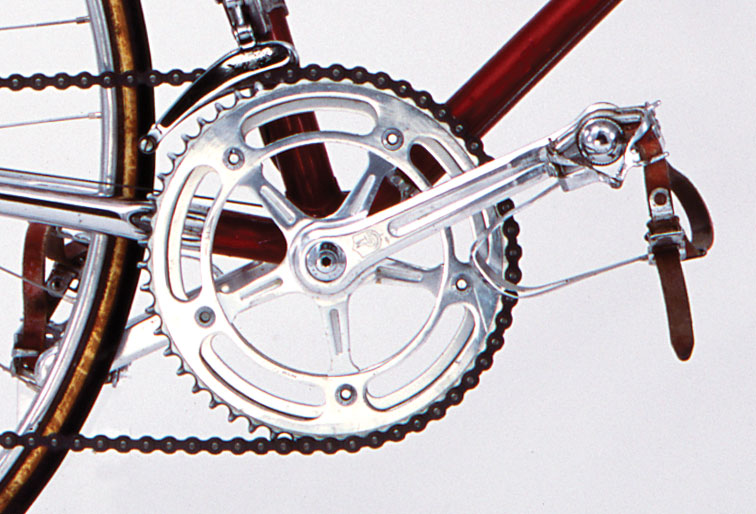

When Campagnolo offered his first cranks in 1958 (above, 1965 version shown), Campagnolo used five arms for the spider instead of Herse’s three arms. Did he think that racers needed more support for the chainrings? Actually, the real reason probably has more to do with manufacturing: Five arms make it much easier to control the runout of the chainrings. At the time, most racers used a small chainring with 47 teeth. Campagnolo probably figured that no racer would ever want fewer than 43 teeth, and he chose a 151 mm bolt-circle diameter.

Around the same time, triple cranks were becoming popular among racers. Campagnolo offered a “Strada” model that simply used longer chainring bolts and nuts, plus spacers, so you could bolt a third chainring to your cranks. Of course, a triple with a small ring of 43 teeth was of little use to most riders.

Some mechanics instead retrofitted Campagnolo cranks with a third ring, with a smaller bolt circle (from Stronglight or TA). They drilled holes into the crank’s spider, tapped them, and attached the third ring with spacers. The photo above shows one of these home-made conversions. Since it’s a tandem, you see a fourth chainring, which is on the other side of the bike.

In the 1970s, Campagnolo began offering a factory-made version of this design. The Campagnolo triple appears to have been the first production crank with two different bolt-circle diameters.

For decades, most component makers copied Campagnolo, sometimes with small modifications. Shimano’s cranks used a 130 mm bolt-circle diameter that allowed using chainrings down to 38 teeth. Campagnolo reduced their bolt-circle diameter first to 144 mm (42-tooth chainrings), then to 135 mm (39-tooth chainrings).

When mountain bikes popularized triple chainrings, the crank makers copied the dual bolt-circle diameter of the old Campagnolo “retrofit” triple cranks (above; the second set of bolts is hidden on the other side of the crank). Component makers reduced the bolt-circle diameters to allow the use of smaller chainrings, but did not reexamine whether it made sense to have two different bolt circles on the same cranks.

During the 1980s, Campagnolo tried to break away from the dual-bolt circle diameter “retrofit” cranks. Their Gran Sport Touring, Victory and Triomphe cranks had a smaller 116 mm bolt-circle diameter (above), so they could be equipped as doubles or triples, with chainrings down to 36 teeth. (It appears that Campagnolo could not envision anybody using rings smaller than 36 teeth.)

The basic idea was sound, but it fell by the wayside as Shimano began to dominate the component market. When Campagnolo offered a road triple again in the 1990s, they were back to two different bolt circles.

In recent years, Shimano’s mountain bike cranks have moved away from the five-arm spider. To save weight, they now use four arms. However, the two bolt circles remain.

On triple cranks for the road, Shimano remains faithful to the tradition of five-arm spiders and multiple bolt circles, even though the extra arms and larger bolt circle for the outer rings provide no real advantage.

In recent years, many riders found they needed chainrings smaller than the 39- or 38-teeth offered by racing cranks. Crank makers have offered additional “compact” models (above) with a 110 mm bolt circle. This bolt circle limits the smallest ring to 34 teeth, even though many riders could use smaller chainrings. The crank makers continue to offer the larger bolt circles for their “standard” cranks.

Even today, the old René Herse design remains the most logical: It allows using any chainring combination. It’s lighter than most modern cranks, because it uses only as much material as needed. The Herse cranks did not serve as a template for the industry because they were too rare and mostly unknown when “modern” cranks were introduced during the 1980s, 1990s and 2000s. Instead, everybody copied Campagnolo’s cranks, which initially were intended for ultra-strong racers, and then retrofitted with a third chainring for those not strong enough to climb hills in a 42-tooth chainring. It appears that nobody took a clean sheet of paper and tried to come up with a more rational design for a bicycle crank.

We are proud to reintroduce René Herse cranks, so that today’s cyclists can enjoy the benefits of light weight, narrow tread (Q factor), unlimited chainring choices, and easy setup.